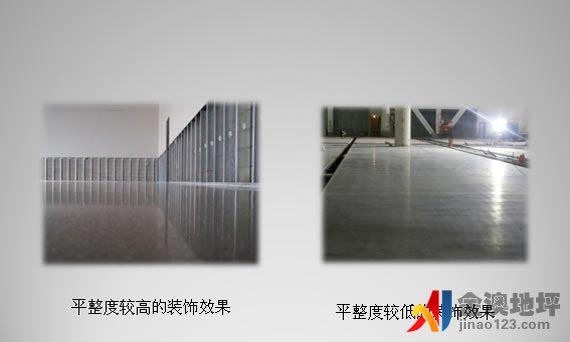

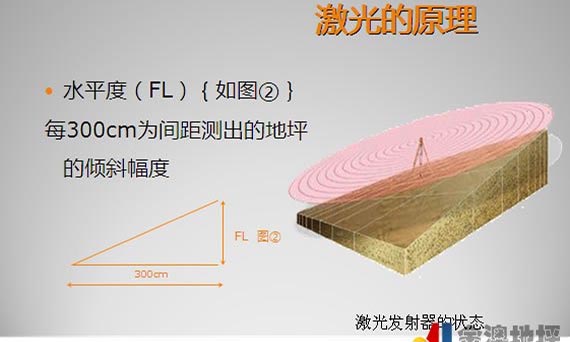

Ngati mukufuna kupanga bwino kuvala zosagwira pansi (kapena apamwamba kuchiritsa infiltration pansi), muyenera kuthana ndi mphamvu ya maziko konkire, makamaka flatness.Pansi yabwino yosamva kuvala sikungogwirizana kwambiri ndi mtundu wa aggregate osavala.Malo abwinoko oyambira amafunikira.Pepalali likufuna kukupatsirani ukadaulo wokwanira komanso wokwanira wa laser konkriti komanso ukadaulo wapansi wosavala.Zomwe zili m'munsizi ndi njira zomangira zomwe zafotokozedwa mwachidule ndi Shanghai Jiezhou Engineering & Mechanism Co., Ltd. malinga ndi zaka zambiri zamakampani.Kwa umboni wanu.

Njira yomanga: chithandizo chamankhwala oyambira → kuyika kosungirako → kudyetsa konkire → makina opangira ma laser, kunjenjemera ndi kuphatikizika → kufalitsa zitsulo zophatikizira → kutulutsa zitsulo → kutulutsa matope → kupukuta → kuthirira ndi kuchiritsa → kudula kolumikizana ndi mawotchi.

Chithunzi chopanga laser screed

Chithandizo chapansi

1. Choyamba, zinyalala zomwe zili pamsinkhu wapansi zidzachotsedwa ndipo sipadzakhalanso zosiyana pamwamba pa njira yoyambira.

2. Tchulani mbali yotuluka pamwamba kuti pamwamba pakhale yunifolomu.Yang'anani ngati kusalala kwa kosi yoyambira kukugwirizana ndi ± 2cm kuchokera pamalo okwera kuti muwonetsetse makulidwe a konkriti.

Zokonda pazithunzi

Choyamba, molingana ndi malo achitsulo a chomera chonsecho, zofunikira za kapangidwe kake, kukonzekera kwa formwork, mayendedwe oyenda pagalimoto ndi mawonekedwe omanga a zida zowongolera, njira yodalirika yotsatsira imapangidwa.Formwork yolimba iyenera kukhazikitsidwa pamalo omanga.Mawonekedwewa adzakhala mawonekedwe apadera opangidwa ndi chitsulo chachitsulo, ndipo kutsegulira kwapamwamba kwa mawonekedwewo kudzasinthidwa kuti ikhale yosalala komanso yosasinthasintha mkati ndi kunja.

Khazikitsani wosanjikiza wotsetsereka

Pambuyo pokhazikitsidwa, malo omangawo adzaphimbidwa ndi filimu ya pulasitiki kuti alekanitse njira yoyambira kuchokera pamwamba pa konkire kuti apange wosanjikiza wotsetsereka.

Kumanga kulimbikitsa mauna

1. The reinforcement mesh idzasinthidwa ndi batching yapakati ndi yogwirizana pamalopo, ndikupita kumalo osankhidwa kuti asungidwe pambuyo pomanga.Kulimbitsa pamwamba kudzakhala koyera, kopanda dothi, dzimbiri, ndi zina zotero kuti zitsimikizire mtundu wa zipangizo.Ma mesh olimbikitsa azikhala omangika kwathunthu, ndipo masinthidwe ndi kukula kwake kukwaniritse zofunikira ndi kapangidwe kake.Pambuyo pomangiriza, yang'anani mauna olimbikitsa kuti muwone ngati gawo lotetezera ndilokwanira, ngati kumangako kuli kolimba komanso ngati pali kumasuka.

2. Musanatsanulire konkire, idzaikidwa pamalo osankhidwa ndi ogwira ntchito.Kukula kwa mauna olimbikitsa ndi 3M × 3m.

Kupanga makina opangira laser

Musanayambe kuthira konkire, makina opangira laser ayenera kuchotsedwa.Imikani ndikuwongolera cholumikizira cha laser, ndikusintha mulingo ndi kutalika kwa mutu wowongolera wa makina owongolera konkriti molingana ndi chizindikiro chopatsirana kuti chigwirizane ndi kutalika kwa nthaka ya konkire.Panthawi imodzimodziyo, sinthani kusiyana kwa kutalika kwa malekezero onse a mutu wosanjikiza mkati mwa 0.5mm.Musanayambe kumanga kwakukulu, choyamba gwiritsani ntchito zipangizo zopangira mayesero ndikuwonetsetsa kuti palibe cholakwika.

Kuthira konkriti

1. Konkire yamalonda idzagwiritsidwa ntchito.Kugwira ntchito kwa konkriti yamalonda kudzakwaniritsa zofunikira, ndipo kutsika kwa konkriti mu mawonekedwe apangidwe kumayendetsedwa pa 160-180mm.

2. Konkire idzayala kuchokera kumapeto mwadongosolo.Pamene kusakaniza konkire kutsanuliridwa mu formwork, kutsitsa kudzakhala kokhazikika komanso pang'onopang'ono, ndipo makulidwe ake adzakhala pafupifupi 2cm kuposa mawonekedwe.Ngati ndi kotheka, zinthuzo zidzachepetsedwa kapena kuwonjezeredwa, ndipo zigawo zowongoka ndi zopingasa zidzakwaniritsa zofunikira.Konkire iyenera kukonzedwa mosalekeza popanda kusokoneza.

3. Pambuyo kutsanuliridwa konkire, milu ya konkire iyenera kuyendetsedwa mozungulira pamanja mkati mwa makina ogwira ntchito a telescopic a makina oyendetsa, ndiyeno kugwedezeka, kugwedeza ndi kusuntha kudzamalizidwa nthawi imodzi ndi makina opangira laser.Posanja, tengani njira imodzi monga mfundo, ndikugona chammbuyo kuchokera mkati kupita kunja sitepe ndi sitepe.

4. Malo omwe kumangidwa kwa makina sikungatheke, monga ngodya ndi zitsulo zazitsulo, ziyenera kuphatikizidwa ndi kusinthidwa pamanja.

Valani zomangira pansi zosagwira

Pamaso pa konkire koyambirira, thaulo la disc liyenera kugwiritsidwa ntchito popaka pulasitala mpaka slurry itatulutsidwa, ndipo chowumitsa chigawidwe mofanana pa konkire.Pambuyo chowumitsa chiyamwa madzi enaake, yambani kugaya;Pambuyo pogaya movutikira, gawo lachiwiri la chowumitsa lidzafalikira, ndipo kuchuluka kwa zinthu kudzakhala 1/3 ya zomwe zidachitika kale.Kugaya pamtanda kudzachitika panthawi yopera, ndipo palibe kugaya komwe kumaloledwa.

Kuphatikizika kwa trowel ndi kupukuta

1. Pambuyo pakuwongolera kwa laser, konkire idzakwezedwa ndikumalizidwa ndi trowel isanayambe komanso itatha kukhazikitsa koyamba.The troweling ntchito chopukusira chimbale adzachitidwa kwa nthawi zambiri malinga ndi kuumitsa pamwamba wosanjikiza.Liwiro la ntchito ya makina troweling adzakhala kusinthidwa moyenera malinga ndi kuumitsa pansi konkire, ndi makina troweling ntchito idzachitika vertically ndi horizontally.

2. Musanakhazikitse komaliza, sinthani diski ya chopukusira ngati tsamba, ndikusintha ngodya yopera ndi kupukuta.Nthawi zambiri, ntchito yopukutira imakhala yopitilira 2 kuti apange gloss yunifolomu.

Mpata:Malumikizidwewo adulidwe munthawi ya 2-3D mutatha kupanga njira yosagwira pamwamba.Kudula konyowa kumayenera kutengedwa podula mfundo, ndi makulidwe a 5cm ndi kuya kosachepera 1/3 mwa makulidwe a konkire.Msoko wodula udzakhala wowongoka komanso wokongola.

Kuchiritsa: Pambuyo popukutidwa konkire, imakutidwa ndi filimu ndikuthirira madzi kuti achiritsidwe.Pa nthawi yochiritsa, mphamvu ya konkire ya pamtunda sifika 1.2MPa, palibe amene angayendepo.

Caulking

1. Pambuyo pochiritsidwa kwa masabata awiri, yeretsani bwino chodulacho ndikuchotsani tinthu tating'onoting'ono ndi fumbi pamagulu odula.

2. Polyurethane sealant yokhala ndi elasticity yokhalitsa komanso kuchiritsa mwachangu idzagwiritsidwa ntchito kudzaza mgwirizano wa shrinkage.

Njira zowongolera

1. Zida zomwe zimagwiritsidwa ntchito pa malowa ziyenera kuvomerezedwa ndi malo, ndipo zidzayikidwa pamalo osankhidwa pambuyo podutsa kuvomereza.Zindikirani kuti zida zomwe zili ndi zofunikira zosalowa madzi ziyenera kuchitapo kanthu motsutsana ndi chinyezi ndi mvula.

2. Kupereka anthu odziwa ntchito yoyang'anira zomangamanga komanso odziwa ntchito zomangamanga.Asanamangidwe, ogwira ntchito oyenerera adzakonzedwa kuti awonetsere luso la kugwiritsa ntchito makina omanga ndi zida ndi kuwongolera njira zazikuluzikulu, kuti awonetsetse kuti ogwira ntchito yomangayo ndi odziwa bwino ntchito iliyonse.

3. Makina omanga ndi zida azikwaniritsa zofunikira, kukhala bwino, ndikukonzekera zida zina zofunika.

4. Malo omangira malo azikhala aukhondo komanso mwadongosolo kuti fumbi ndi zina zisawononge nthaka.

5. Matumba, zinyalala ndi zinyalala zina zomwe zatsala pamalowa zizichotsedwa tsiku lililonse kuti zitsimikizire kuti malowo achotsedwa ntchito.Pakawonongeka zipangizo zapadera, njira yochiritsira idzakhala yogwirizana ndi zofunikira zothandizira zipangizo zapadera.

Potsirizira pake, kuwonjezera pakutsatira mosamalitsa ndondomeko zomwe zili pamwambazi, malo abwino osamva kuvala amafunikiranso kugwirizanitsa ndi mgwirizano pakati pa konkire ndi pansi osavala.

Yakhazikitsidwa mu 1983, Shanghai Jiezhou Engineering & Mechanism Co., Ltd. imayang'ana pa R & D, kupanga ndi kugulitsa makina pamunda wa konkire pansi.Laser screed makina, trowel mphamvu, makina odulira, mbale compactor, tamping rammer ndi makina ena amagwiritsa ntchito ukadaulo waposachedwa ndipo amayamikiridwa kwambiri ndi makasitomala.

Ili ndi makasitomala m'maiko oposa 100 padziko lonse lapansi ndipo ndi mtsogoleri pamakampani.Ngati muli ndi mafunso, mutha kuyimbira DYNAMIC, ndipo tidzakutumikirani ndi mtima wonse!

Nthawi yotumiza: Aug-24-2022